TAURUS Gemini High Rail Milling Machine

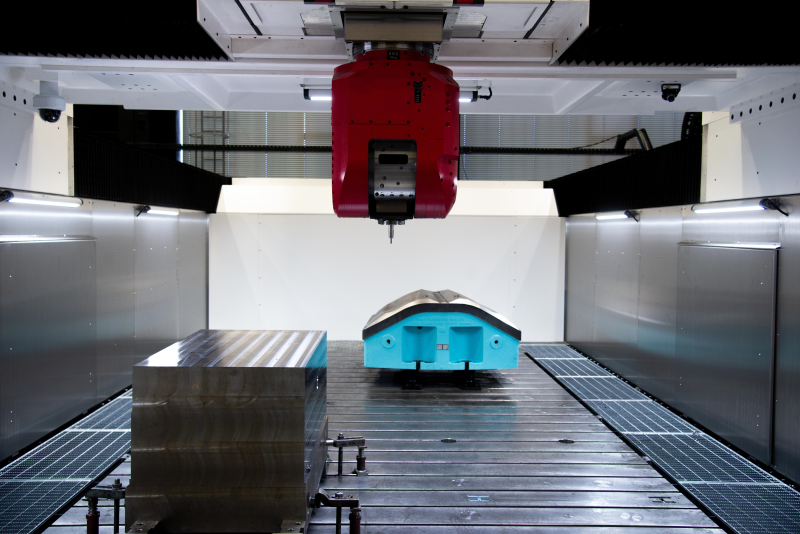

The TAURUS Gemini is the latest addition to the Waldrich Coburg family of milling machines, consolidating the features of our MultiContour high rail gantry mill into a compact, production-built package. With high dynamic stiffness and fully hydrostatic guideways, this design allows for higher feed rates while still maintaining the superior accuracy for which Waldrich Coburg is world-renowned. Optional rotary table integration can expand the TAURUS Gemini’s capabilities threefold, combining milling, turning, and grinding operations into one do-it-all dynamo.

Interested in more information?

Why the TAURUS Gemini High Rail Milling Machine?

Magnificently multifunctional

The integrated rotary table option empowers the TAURUS Gemini to do more with less floor space — milling, turning, and grinding in a single CNC vertical machining center.

A model of efficiency

The TAURUS Gemini’s gantry-style design allows for higher feed rates and increased stability; automatic tool and spindle unit changers and other process automation features maximize spindle up-time.

Longevity by design

Our proven hydrostatic guideway system utilizes pressurized oil to virtually eliminate friction, vibration, and wear, prolonging your machine’s lifespan and reducing cost.

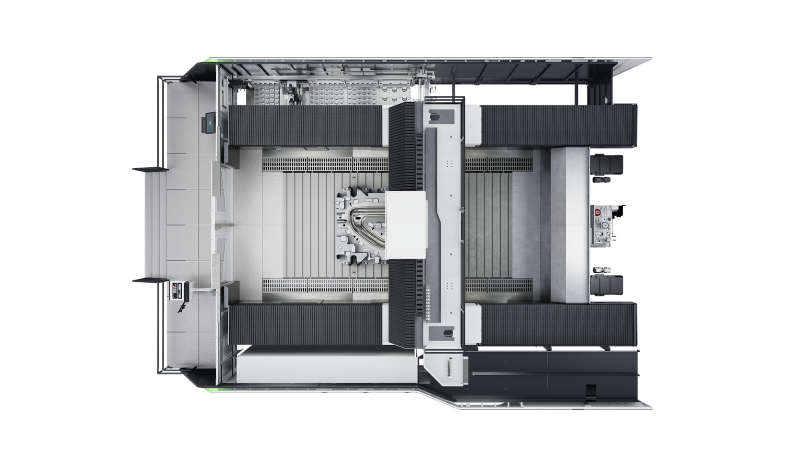

TAURUS Gemini High Rail Gantry Milling Machine Specs

| Travels | X-Axis: 4.300 mm/7.200 mm Y-Axis: 4.000 mm |

| Z-Axis | 1.500 mm |

| Max. feed | 40 m/min in X/Y/Z |

| Rapid |

40 m/min in X/Y/Z |

| Acceleration | 3 m/s² in X/Y/Z |

| Table load | 5.000 kg/m² |

| Optional turning table | Diameter 3.300 mm; Load 12.000 kg, 120 min-1 |

| Main drive | 6.000 min-1; 45 / 63 KW 1.250 Nm / 1.500 Nm (S1 / S6) |

| Motor spindle | 20.000 min-1; 30 kW; 70 Nm |

| Tool changer | 60 / 120 places |

| Dimensions of tools | Ø 135 mm (Ø260 mm*), length 600 mm |

| Tool weight | 20 kg / 30 kg in single change |

| Machine weight | ~ 190 t |

* For tool diameters > 135 mm, the number of tool positions is reduced

View All Vertical Bridge Mills