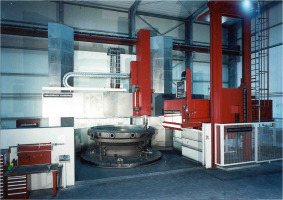

MultiTurn CNC Vertical Turning Lathe

Diverse and powerful in its capabilities, the MultiTurn CNC vertical lathe is Waldrich Coburg’s proprietary solution for machining complex medium and large workpieces, combining turning and milling operations into one highly efficient unit. As with our other VTL machines, MultiTurn can be equipped with a vast array of turning and milling spindle units, with automatic tool and head changers to minimize non-cutting time and maximize productivity. Its versatility and precision make it a valuable asset in numerous applications, especially the power generation industry.

Interested in turning up productivity on your workshop floor?

Everything you need a CNC vertical turning lathe to do

Cuts time

Utilizing the Masterhead concept, MultiTurn CNC vertical lathe can change turning and milling spindle units on the fly. This and other automation features mean fewer stoppages for your shop.

Cuts complex parts

Our portal design combined with an optional movable Y-axis rotary table helps maneuver workpieces with ease, removing material with extreme accuracy in virtually any direction you need it to.

Cuts costs

Complete turning and milling operations within a single setup on a single machining center, reducing scrap rate and increasing accuracy. The MultiTurn is ideal for shops with moderate volume demands.

MultiTurn Vertical Turning Machine Characteristics

| Design | Portal Design |

| Turning Table | Stationary/Movable |

| Crossrail | Fixed/Movable |

| Swing Diameter | 4000 – 6000 mm (157.5 – 236 in.) |

| Turning Height | 1000 – 5000 mm (39.4 – 197 in.) |

| Rotary Table Drive Power |

100 – 200 kW (134 – 268 HP) |

| Weight of Workpiece | 80 tons |

View All Vertical Turning Machines