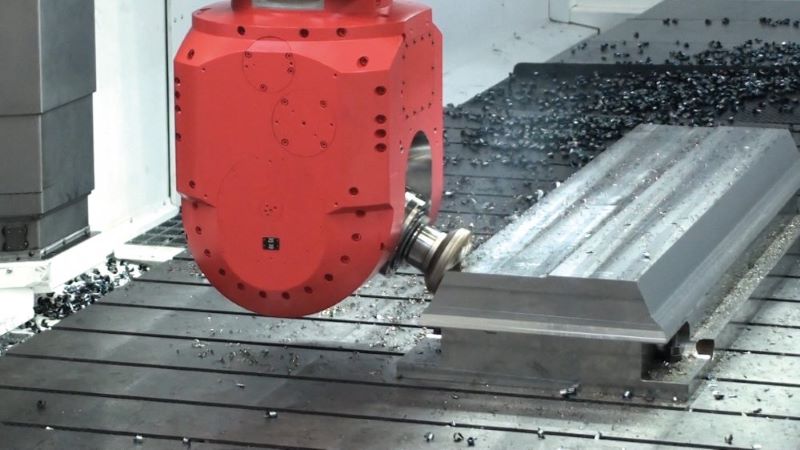

TAURUS Vertical Machining Center

Powerful, precise, and wear-free, the TAURUS vertical machining center leads the charge over other CNC vertical mills in its class. Dimensionally, it can be scaled up or down to fit your parts. Operationally, it can be equipped with a host of features and components for optimum functionality.

As with all Waldrich Coburg vertical CNC machines, the TAURUS includes an integrated tool changer, spindle unit changer, coolant system, and machine guards. Best of all, it also includes the same frictionless hydrostatic guideways as our custom-built machines, something you will not find in any other standard-built CNC vertical milling center of this category.

Interested in more information?

What Does the TAURUS Have to Offer?

Versatility.

As is, the TAURUS is wide-ranging in its capabilities, from basic frames to 5-axis machining of exotic materials to high-speed machining of aluminum alloys. It is available with a variety of spindle units and can optionally include a pallet changer for increased efficiency.

Economy.

Standard builds keep production costs down while preserving quality. You know exactly what you’re getting, and so do we — a strategic initial investment to boost shop productivity. TAURUS is designed for flat foundations and should fit in right away.

Longevity.

Hydrostatic guideways virtually eliminate friction and wear for long life and increased accuracy. The TAURUS’ interactive production and diagnostics system allow operators to swiftly troubleshoot and address maintenance issues.

TAURUS Characteristics

| Power (S6/S1) | 63/45 kW (85/63 HP) |

| Clearance Width | 2000 - 3500 mm (78 - 138 in.) |

| Setup Length | >2000 mm (78 in.) |

| Clearance Height | 1500 - 3000 mm (59 - 118 in.) |

| Ram Stroke | 1500 mm (59 in.) |